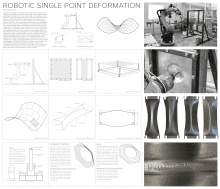

Pinned Incremental Metal Forming

DesComp Thesis completed by Paul Stockhoff (2017)

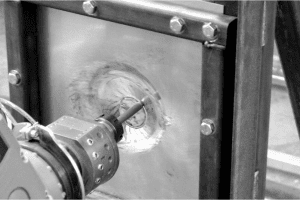

Slip Mounted Single Point Deformation expands upon the ideas of single point incremental metal forming, using a 6-axis robotic arm, by exploring the possibilities of how sheet metal can be deformed with minimal support bracing. The goal of this technique and research is to develop controlled methods for fabricating precise, double-curved, structural panels. The slip mounted technique requires mounting a piece of material in the vertical plane while only bracing two edges of the sheet. The material in this method is allowed to stretch, flex and twist during forming unlike in traditional incremental metal forming. Single point incremental forming is the process in which a hardened metal stylus is attached to either a robotic arm or CNC machine and then programmed to trace the contours of a shape gradually into a deformed piece of metal, allowing for far more complex shapes than traditional forming methods. While each pass is made the piece of equipment pushes between .3mm – 1mm causing the sheet to deform into the desired geometry. During the development period of the single point incremental forming process, we identified three control variables; tool design, tool path generation, and the deformation limits of 20-gauge cold rolled steel sheets for doubly-curved surfaces. This initial research, along with explorations by others, became the underpinning for the work examined in this paper, where single point incremental metal forming is used to create doubly-curved panels which can create a self-supporting structural surface.